Cell therapy represents a promising new field of medicine, especially in the treatment of diseases such as cancer, inflammatory and chronic degenerative diseases, by manipulating or replacing cells to restore function or fight disease. However, the main challenge in CTP manufacturing is to quickly and effectively ensure that there is no contamination before administering to the patient before administering to the patient.

Existing sterile testing methods based on microbiological methods are labor-intensive and take up to 14 days to detect contamination, which can adversely affect critically ill patients who require immediate treatment. Advanced technologies such as the Rapid Microbial Method (RMM) can reduce the testing period to 7 days, but they still require complex processes such as cell extraction and growth enrichment medium and are highly dependent on skilled workers for processes such as sample extraction, measurement, measurement and analysis. This urgently requires new approaches that can provide faster results without compromising the quality of CTP, meeting patient usage schedules, and using simple workflows without requiring additional preparation.

This method has significant advantages over both traditional sterile tests and RMMs, as it eliminates the need for cell staining to identify labeled organisms, avoids the invasive process of cell extraction, and provides half an hour. It provides intuitive, fast “yes/no” contamination assessments that promote automation of cell culture sampling with a simple workflow. Furthermore, the developed method does not require specialized equipment, thus reducing costs.

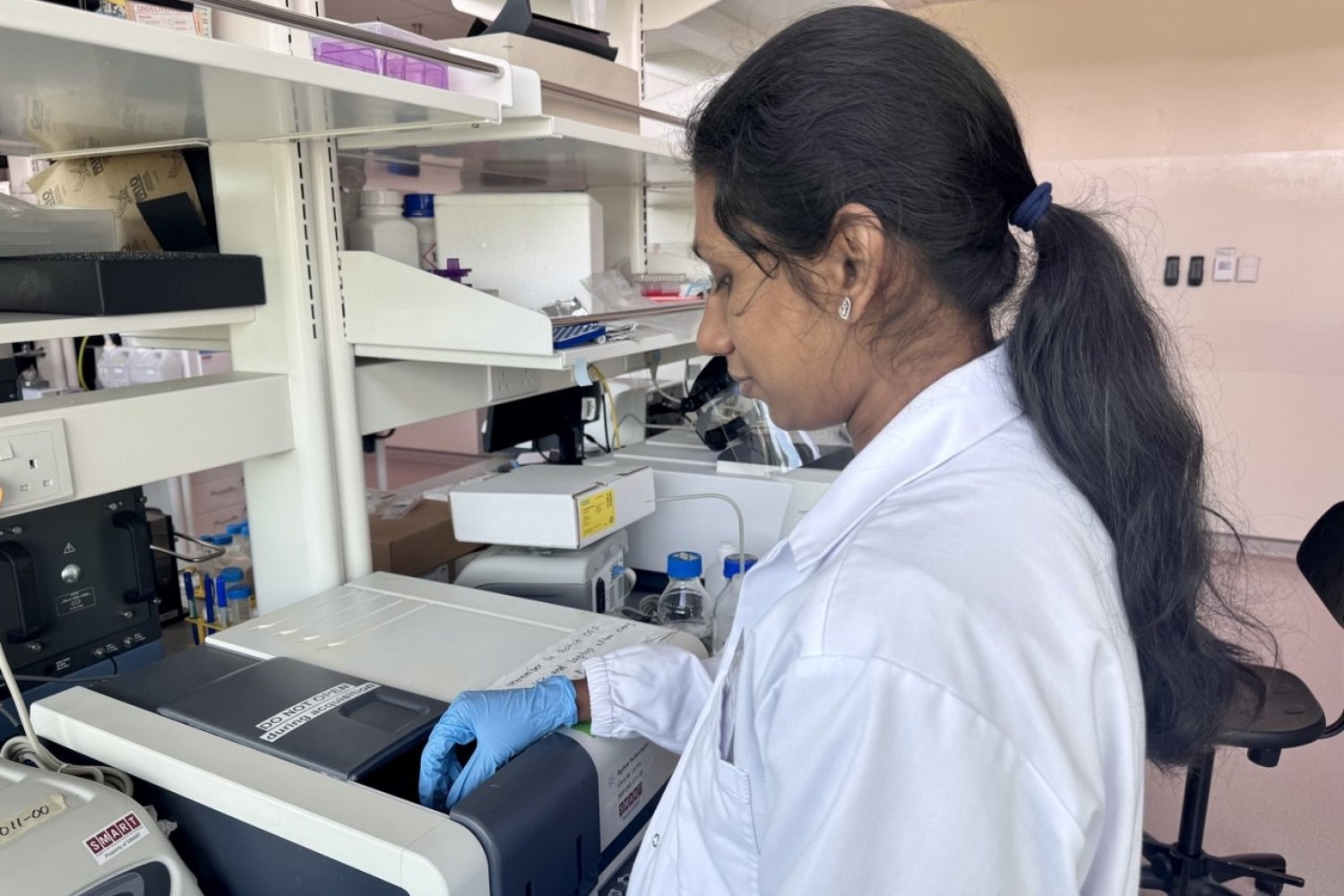

“This rapid, label-free method is designed to be a preliminary step in the CTP manufacturing process as a form of continuous safety testing, which allows users to detect contamination early and implement timely corrective actions, including the use of RMMs only when possible contamination is detected. This approach saves costs, optimizes resource allocation, and ultimately accelerates the overall manufacturing timeline,” says Shruthi Pandi Chelvam, senior research engineer at SMART CAMP and first author of the paper.

“Traditionally, cell therapy manufacturing is labor-intensive and subject to operator variability. By introducing automation and machine learning, we hope to simplify cell therapy manufacturing and reduce the risk of contamination. Specifically, our approach supports automated cell culture sampling at specified intervals to check for contamination to reduce such cultures and analysis, and analyze such cultures such as gradual overview, and analyze these cultures and perform analysis. It was detected at an early stage.

Moving forward, future research will focus on expanding the application of this method to cover a wider range of microbial contaminants, especially those representing the current good manufacturing practice environment and previously identified CTP contaminants. In addition, the robustness of the model can be tested on more cell types in addition to MSCs. In addition to cell therapy manufacturing, the method can also be applied in the food and beverage industry as part of microbial quality control testing to ensure food meets safety standards.

1005 Alcyon Dr Bellmawr NJ 08031

1005 Alcyon Dr Bellmawr NJ 08031